Tingpacking Order Tracking

When our order is officially opened, you can timely know the progress of order execution through our online order tracking system.

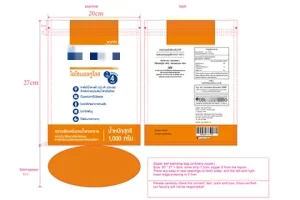

Know How Produced

What The Order Process?

As a professional manufacturer of flexible packaging bags, we follow a comprehensive process for custom production of these bags.

Raw Material Selection

We carefully choose the raw materials for plastic packaging bags based on the client’s product and packaging requirements. The material selection varies according to the specific product to ensure the bags have the appropriate functionalities.

Design Draft

Starting with a blank template, we render the brand’s colors and design elements to bring the brand’s identity and value to life in a complete design draft.

Plate Making

According to client specifications, we create printing plates for the reproduction of designs. Common plate types include photopolymer plates, copperplates, flexographic plates, and silk screen plates, with copperplates being the most prevalent.

Printing

We translate the designs and text from the design drafts onto the printing plates, apply ink to these plates, and then transfer the inked images onto the packaging material through pressure. This process yields printed products identical to the original design. Printing encompasses surface printing and reverse printing.

Lamination

Our lamination process involves bonding two or more layers of materials together using adhesives or other intermediaries, enhancing the overall performance of the packaging film and bags. This process is referred to as the lamination process.

Curing

Curing is conducted to expedite the solidification of adhesives between layers, ensuring a robust bond between materials.

Slitting

The printed and laminated materials are precisely slit into the required specifications to meet customer needs.

Bag Making

Utilizing the printed, laminated, and slit materials, we create various bag types according to customer requirements, such as flat pouches, side seal pouches, stand-up pouches, K-seal pouches, R-seal pouches, quad seal pouches, and zipper pouches.

Quality Control

Our quality control measures encompass pre-receiving inspection of raw materials, in-line product testing, and a final quality check before shipment. These measures ensure that the products adhere to established standards.

Packaging

All bags are packaged in sets, commonly either 100 or 50 units per OPP bag. These sets are then placed within reinforced, multi-layer cardboard boxes, further protected with transparent stretch film to prevent moisture and humidity damage. The outer boxes are labeled to identify the product contents.

Shipping

After the packaging process is complete, the next steps involve arranging shipping, freight forwarding and tracking and monitoring for the packaged goods. This includes loading the products onto transportation vehicles and handling various shipping terms, such as FOB (Free On Board).